About the Department

The Department of Automobile Engineering was established in the year 2011 with a mission to prepare highly competent Automobile Engineers for global automotive industries through innovative, industry-oriented curriculum, intensive practical training, and industry exposure to the students in the thrust areas (Automotive Design and Automotive Electronics and Automotive service). The Department focuses on offering industry exposure to the students and train them through Industry projects in the specialized stream of their choice. Major areas of research interest are the Hybrid and Electric Vehicle Technologies, Vehicle Design & Performance optimization and Vehicle Maintenance.

From the HOD’s Desk

Dr. J. D. Andrew Pon Abraham,

Assistant Professor II & Head

The primary focus of our curriculum is to provide technical knowledge to students, promote their problem-solving skills and render solutions for the real life automotive engineering problems. The Department offers Professional Electives, Industry-oriented one-credit and Open Elective courses for acquiring wide spectrum of interdisciplinary knowledge. The course contents are periodically updated in consultation with the experts from the industry considering the scientific and technological developments. Students utilize the state of the art laboratory facilities for improving their skill sets in their areas of interest.

Vision

To be a renowned Learning Centre in the field of Automobile Engineering contributing towards development of the society.

Mission

To attain the Vision, the department will

- Develop students for successful careers in Industry, and Academia.

- Provide required learning environment and processes to become socially responsible Engineering Professionals.

- Establish Industry-Institute interaction

- Inculcate the entrepreneurial mind set among the students.

UG-B.E. Automobile Engineering 4 Years (8 Semesters)

Program Educational Objectives (PEOs)

- PEO 1: Design and develop products, utilize their knowledge and skills as maintenance engineer / start their own ventures as entrepreneurs.

- PEO 2: Practice managerial and leadership roles with values and social responsibility

- PEO 3: Pursue higher studies and research in core, allied fields and management.

Programme Outcomes (POs)

- PO1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

- PO2: Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- PO3: Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

- PO4: Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- PO5: Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations.

- PO6: The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

- PO7: Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- PO8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

- PO9: Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- PO10: Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

- PO11: Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

- PO12: Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Programme Specific Outcomes (PSOs)

At the end of the program, the students will be able to:

- PSO1: To provide solutions for designing safe and affordable automotive and mobile equipment.

- PSO2: To explore the Automotive Manufacturing, Automotive Electrical & Electronics and vehicle maintenance and service domains.

- Automobile Engineering Program started in the year 2011-12.

- Hosted National Go-kart Championship, NGKC-2014 conducted by ISNEE in Oct 2014

- Dirt Track set up and Mini Dirt Bike Competition sponsored by Hero MotoCorp in Feb 2015

- First National Conference on “Recent Advancements in Automotive System – Design, Manufacturing & Integration conducted in March 2015.

- Quad Bike Design Challenge – Season 2 with Fraternity of Mechanical Engineers Association in Oct 2016

- Robert Bosch Centre for Automotive Electronics in Nov 2017

- Mini Dirt Bike Competitions sponsored by Hero MotoCorp conducted in March 2016 & 2017.

- Anna University Approved one week FDTP on the topic “ME6603 – FINITE ELEMENT ANALYSIS” during May 2017.

- 3 Day Proficiency Improvement Program (PIP) on “Futuristic Automotive Technologies” with Automotive Research Association of India in August 2017

- One Day International Workshop on Motorsports Engineering in association with ARA Institute of Canterbury, New Zealand in Jul 2016 & Oct 2017

- Crash Course on Motorsport Engineering during Oct 2017 in partnership with ARA Institute of Canterbury.

- Optimum G – Advanced Vehicle Dynamics Seminar – Sessions handled by international motorsport expert Mr. Claude Rouelle, CEO – Optimum G during Feb 2018.

- KCT Mini Dirt Bike Competition conducted in Feb 2018.

- Second National Conference titled “Automotive Systems Design, Manufacturing and Integration” (ASDMI 18) on 28th April 2018.

- FFS India 2018 in association with Fraternity of Mechanical and Automotive Engineers.

Automotive Chassis Laboratory

- Laboratory Area: 113.85 Sq.m

- Equipments Cost: ₹ 15,12,924

List of Equipments:

Cut Section Working Model of LCV Chassis with following systems mounted on the chassis

- Rear Axles

- Differential Units

- Diaphragm Clutch Assembly

- Single Plate Clutch Assembly

- Multiplate Clutch Assembly

- Gearbox (Light Duty)

- Gearbox (Heavy Duty)

- Power Steering system

- Steering Gear boxes

- Front Axle with Steering and Suspension assembly

- Pneumatic Brake System

- Hydraulic Brake System

- Automatic Transmission Gearbox

- Four Wheel Drive Transfer box

- Hydraulic Servo Vacuum Brake (Motorized vacuum brake pump)

- Epicyclic Gear Box Model

Automotive Electrical and Electronics Laboratory

- Laboratory Area: 139.41 Sq.m

- Equipments Cost: ₹ 5,34,668

List of Equipments:

- CRO

- Transformer 9V

- Dual Power Supply 30A/3A

- Logic Gate Trainer

- Single Power Supply 30A/3A

- Ignition Fault Diagnosis Test Rig

- Rectifier Module

- Cut Section Model of Power Window

- Auto Electrical Test Bench for Alternator and Starter Motor

- Battery Charger

- Battery with Hydrometer and High Rate Discharge Tester

- Microprocessor 8085

- Manual Test Station Of Fuel Cell

- dSPACE Hardware 1104 With Software

- Electronic Ignition System of Two Wheeler

- Electronic Ignition System of Four Wheeler

Automotive Embedded Systems Laboratory

- Laboratory Area: 83.64 Sq.m

- Equipments Cost: ₹ 65,00,000

List of Equipments:

- Workstation 20 Nos.

- MATLAB 2017 Software

- LABVIEW Software

- Proteus 8.8 Software

- Temperature Sensors

- Inductive Proximity Sensors

- Gas Sensors

- Ultrasonic Sensors

- Rain & Moisture Sensor

- IR Sensors

- Hall Effect Sensors

- PIR Sensor

- Vibration Sensor

- Arduino Ethernet Sealed

- Arduino UNO Board

- STL INK V2 – Dedugger

- Node MCU – ESP 8266

- Accelerometer

- 5V & 12V Relay

- 16 X 2 LCD Display

- H Bridge

- Bluetooth HC05

- RF Transmitter and Receiver

- DOT Matrix Display

- GSM Module

- Wifi Chip

- Digital Storage Oscilloscope

- DSRO Sensor

- LDR Sensor

- Sound Finder Sensor

- Stepper Motor

- Servo Motor

- Solenoids

- PIC Microcontroller Boards

- Data acquisition module – Universal RTD USB Based DAQ

- Analog Design Lab Kit

- MSP 430 Launchpad

- ENET 8 slot ENET including power adaptor

- CAN Protocol Learning Kit

- Raspberry Pi Kit</l i>

Engine Components Laboratory

- Laboratory Area: 97.58 Sq.m

- Equipments Cost: ₹ 11,37,438

List of Equipments:

- Cut section model of 2-stroke Petrol engine

- Cut section model of 4 cylinder 4 stroke Carburetor Petrol engine

- Cut section model of 4 cylinder 4 stroke Diesel engine

- Multi cylinder petrol engine for dismantling and assembling – TATA Indica

- Multi cylinder Diesel engine for dismantling and assembling – TATA Safari

- Cut section of Turbocharger

- Cut section of Mechanical Fuel pump

- Cut section of Electrical Fuel pump

- Cut section of Simple 2-wheeler carburetor

- Cut section of Solex 4-wheeler carburetor

- Cut section of Shock absorber

- Cut Section of I.C.Injector (4 Types)

- Cut Section Model of Pumps

- Fuel Pump – Diaphragm type

- Oil Pump

- Vacuum Pump (Vane type)

- Piston Pump (air Compressor)

- Water pump

- Rotary pump

- Model of Cut Sectioned Fuel Injection Pump Assembly

- Pneumatic Governor (Four cylinder engine)

- RQ governor (Six cylinder Engine)

- RSV governor (Six cylinder Engine)

- Distributor (Four Cylinder)

Engine Performance and Emission Testing Laboratory

- Laboratory Area: 97.58 Sq.m

- Equipments Cost: ₹ 10,89,346

List of Equipments:

- BMW Twin Power Turbo Engine

- Multi Cylinder Petrol Engine with Eddy Current Dyno ( 800cc-MPFI )

- Twin Cylinder Diesel Engine with Eddy Current Dyno

- Multi Cylinder Petrol Engine with Eddy Current Dyno ( 1000cc )

- Single Cylinder CRDI Diesel Engine

- Gas Analyzer

- Smoke Meter

- Demonstration of MPFI Engine

- Demonstration of CRDI Engine

Fuels and Lubricants Laboratory

- Laboratory Area: 181.23 Sq.m

- Equipments Cost: ₹ 4,78,103

List of Equipments:

- Fuel analysis Test apparatus

- Abels flash and fire point apparatus

- Aniline point apparatus

- Reid vapour Pressure Test apparatus

- Bomb Calorimeter

- Boys gas calorimeter

- Ramsbottom Carbon Residue apparatus with 5 Nos. Cooking

- Copper Corrosion Test Apparatus

- Cloud and pour point apparatus

- Redwood viscometer

- Say Bolt Viscometer

- Ash content Test

- Distillation Range apparatus

- Standard Penetrometer

- Drop Point Apparatus

- Cut Section Working Model of Lubricating System

Two Wheeler and Three Wheeler Laboratory

- Laboratory Area: 113.85 Sq.m

- Equipments Cost: ₹ 16,65,212

List of Equipments:

- Performance test on Shock absorber & Coil Spring using Pneumatic loading system.

- Two Wheeler Chain Tension Test Rig.

- Brake adjustment

- Clutch adjustment

- Dismantling & assembling of 2 wheeler gear box

- Dismantling & assembling of 3 wheeler gear box and finding gear ratio

- Working model of three wheeler Brake system on a frame

- Working model of three wheeler Clutch system on a frame

- Dismantling & assembling of three wheeler steering,

- Three wheeler chassis frame & Power transmission

- Three Wheeler Suspension Systems.

- Two Wheeler Chassis Dyno – Eddy Current Dynamometer

Vehicle Design and Dynamics Laboratory

- Laboratory Area: 83.64 Sq.m

- Equipments Cost: ₹ 35,40,000

List of Equipments:

Computer Workstation – 40 Nos Specifications:

- Dell OptiPlex 3020 Small Form Factor CTO

- Intel Core i5-4570 Processor (Quad Core, 6MB Cache, 3.2GHz, w/HD Graphics 4600)

- Small Form Factor Chassis Mainstream Heatsink (95watts)

- 4GB 1DIMM NON-ECC, 1600MHz, OptiPlex

- 500GB 3.5inch Serial ATA (7,200 Rpm) Hard Drive

- AMD RadeonHD 8490, 1GB DDR3, LP, 1 DP 1 DVI, Dell OptiPlex

- Dell E Series E2214H 21.5″ Wide Screen Monitor with LED Back Light

- Ubuntu Linux 12.04 (will use campus license for windows)

- Dell USB Entry Keyboard KB212B (English-International)

- Dell MS111 USB Optical Mouse

Softwares Available:

- MSC Nastran’s FEA + Motion Bundle 150 User License Consisting of FEA Bundle – MSC Nastran, Patran, Sinda,Marc & Dytran

- Motion Bundle – MSC Adams, Adams Car & Easy 5

- CarSim software (10 User)

- Autodesk Inventor

- ANSYS R16

Vehicle Maintenance Laboratory

- Laboratory Area: 134.2 Sq.m

- Equipments Cost: ₹ 18,33,677

List of Equipments:

- Tyre Changer Std

- 3D Wheel Aligner

- Wheel Balancer Digital

- Headlight Centering Device

- A/C Recover Fully Automatic

- Brake Bleeding Equipment

- Fault Diagnostic Kit (KTS-540)

- Spark plug Cleaner

- Bearing Puller

- Hydrometer

The department has a departmental library consisting of nearly 441 books covering a wide range of subjects in Mechanical, Automobile, Electrical and Electronics, Management and Basic Sciences. The library also keeps all the previous students’ project reports in hardcopy and softcopy format. The library has several Journals that include IEEE, Springer, ASCE, ASME, McGraw Hill, J-Gate, Elsevier, ASTM Digital Library (Online Version) and IJVSS in collaboration with central library. The books can also be borrowed from premier institute libraries like IITs, IISc and NITs through DELNET service. The following magazines Vehicle Dynamics International, Industrial Vehicle Technology, Professional Motorsports World, Mobility Engineering, Lift Truck Technology, Ricardo, MOTORINDIA, WHATCAR, AUTOINDIA and MODERN MACHINE TOOLS are available for the benefit of students. For the love of visual perception, videos of the latest cars and bikes are available in the department library.

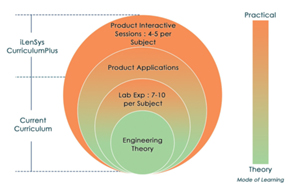

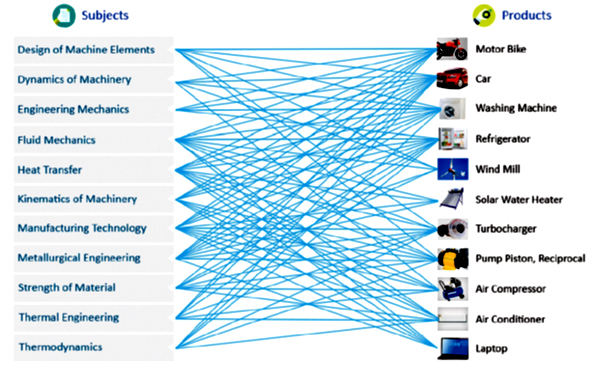

To enhance the fundamental knowledge of the students in basic Engineering Subjects like Engineering Mechanics, Strength of Materials, Fluid Mechanics, Thermodynamics, etc. and also to realize how the concepts are applied in real time application products like washing machine, car, compressor, fridge, etc., this Learning Centre has been established. Demonstration of working models will create interest for students, as they can grasp the concepts easily which enhance the teaching and learning process. Faculty members use this innovative tool to teach Engineering Concepts in a better way by using videos and products. The students are assessed themselves then and there by taking up the Quiz, Assignments in the system as well as uploaded by the respective teachers.

- Design of Machine Elements

- Dynamics of Machinery

- Engineering Materials and Metallurgy

- Engineering Mechanics

- Engineering Thermodynamics

- Fluid Mechanics and Machinery

- Heat and Mass Transfer

- Kinematics of Machinery

- Manufacturing Technology – I

- Manufacturing Technology – II

- Strength of Materials

- Thermal Engineering

Curriculum Plus software are linked to product application, smart lab, engineering theory and interactive products for effective understanding of core concepts.

Product Application Centre The products displayed in the centre are linked to subjects covered in CurriculumPlus software. Some of the features of the Product Application Centre are

- 10+ products from various industries

- Products are placed in the combination of 1) Functional 2) Cut-section and 3) Teared Down

- Application-based learning of engineering concepts

- 50+ interactive activities hands-on and experimental learning

Multiple core subjects are linked with the products which help students to understand the application of different theoretical subjects for making various products.

- Ensures confident and industry-ready engineers

- Improve critical thinking and quick comprehension abilities to write competitive exams like GATE, UPSC etc.

- Developing practical and application oriented knowledge through product application centre (PAC) for Placement Interviews and Projects

- Enables faculty with digital learning system for effective teaching

- Self Learning fundamental Engineering subjects through interactive Curriculum Plus software and application products

Bosch Centre for Automotive Electronics was inaugurated on November 2016. Robert Bosch Engineering and Business solutions limited funded an amount of Rs.600000/- for the purchase of Sensors and Actuators. Sensors and Actuators purchased are given below for the reference. The DEMS kit was supplied by Infineon Technologies, Bangalore to BOSCH centre for Automotive Electronics, at Kumaraguru College of Technology. Lauterbach debugger, DSO and power supply was purchased by KCT from Embedded Systems solutions, Bangalore. Various training programs were conducted by Infineon Technologies, Bangalore to KCT faculty members and students.

Equipments:

| S.No | Equipment Details | Nos | Sponsored by |

|---|---|---|---|

| 1 | Diesel Engine Management System – Demonstrator Kit | 18 | Infineon and Bosch |

| 2 | Power Supply (32V/30A) | 2 | KCT |

| 3 | Lauterbach debugger | 4 | KCT |

| 4 | Carbon Monoxide Sensor – MQ-7 | 5 | Bosch |

| 5 | Color sensor | 3 | Bosch |

| 6 | GAS Sensor MQ 2 | 5 | Bosch |

| 7 | Humidity sensor | 5 | Bosch |

| 8 | IR obstacle sensor with board | 5 | Bosch |

| 9 | Ultrasonic Sensor HC-SR04 | 5 sets | Bosch |

| 10 | Throttle position sensor | 1 | Bosch |

| 11 | speed sensor | 7 | Bosch |

| 12 | Pulse heart rate sensor | 5 | Bosch |

| 13 | hall effect sensors | 8 | Bosch |

| 14 | SM18 proximity detector | 5 | Bosch |

| 15 | Position sensor | 2 | Bosch |

| 16 | REED sensor | 5 | Bosch |

| 17 | Fuel injector | 1 | Bosch |

| 18 | Spark plug | 4 | Bosch |

| 19 | Stepper motor | 2 | Bosch |

| 20 | DC motor | 2 | Bosch |

| 21 | Relays | 1 | Bosch |

Two Wheeler and Three Wheeler:

- Laboratory Area: 113.85 Sq.m

- Equipments Cost: ₹ 16,65,212

List of Equipments:

- Two Wheeler Chassis Dynamometer – Eddy Current Dynamometer

- Shock absorber test rig for Coil spring using Pneumatic loading system.

- Two Wheeler Chain Tension Test Rig.

- Brake adjustment tools

- Clutch adjustment tools

- 2 wheeler gear box

- 3 wheeler gear box

- Three wheeler Brake system

- Three wheeler Clutch system

- Three wheeler chassis frame & Power transmission

- Three Wheeler Suspension Systems.

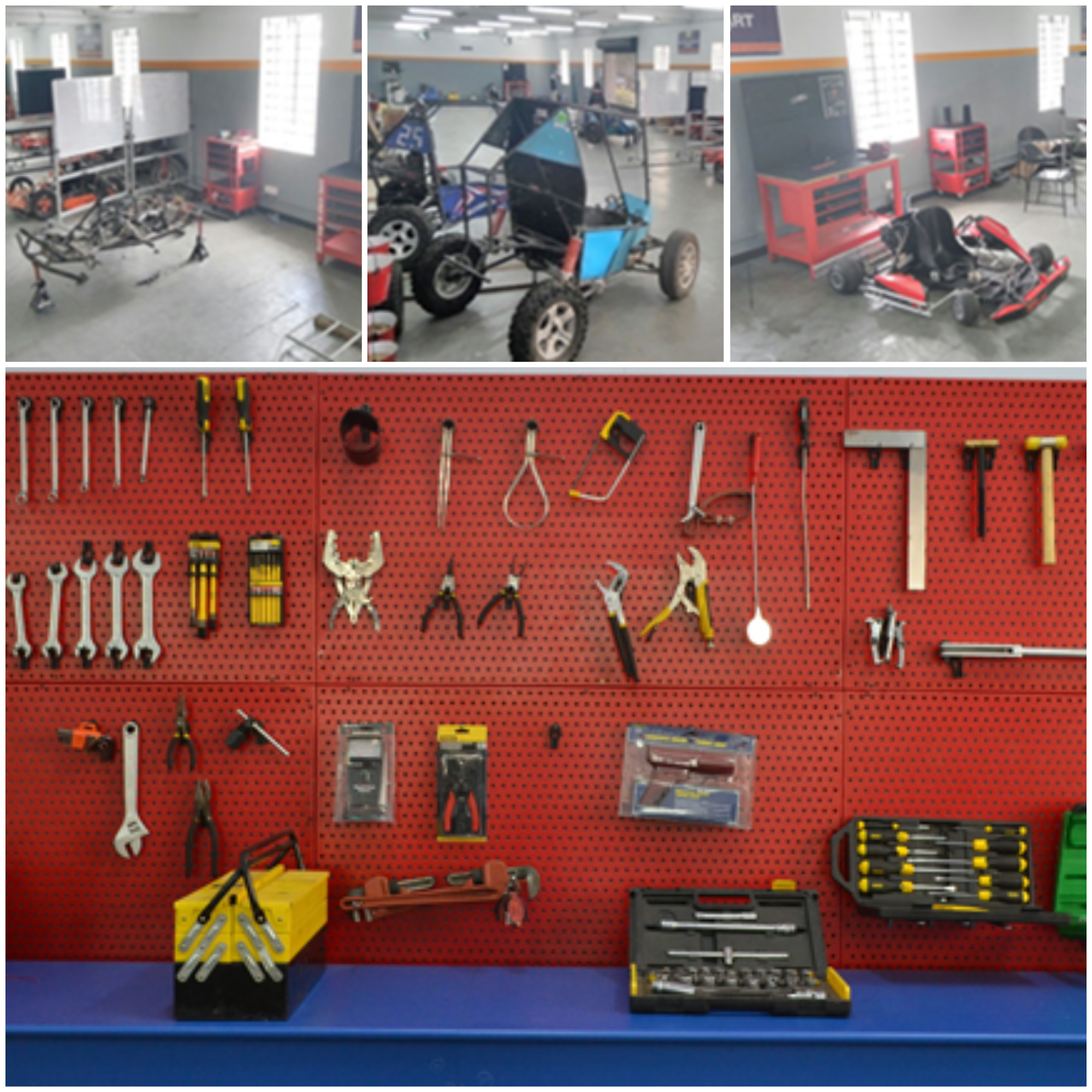

Vehicle Testing Dirt Track, one of its kind in an academic institution is being used for testing Student fabricated Off-road ATVs, Quad Bikes and Dirt bikes and for conducting Motocross events. KCT DIRT Track is about 1.6 km length with multiple turns, Hairpin bends and various obstacles including Camel Jumps, Intermediate Jumps and a Table Top.

6000 Sq Ft of 24 x 7 facility with dedicated bays for fabrication and assembly of All Terrain Vehicles, Go-Karts, Formula Cars, Electric & Solar Karts and Quad bikes for students.

Board of Studies Members

| Dr. S. Jegadheeswaran | Professor & Head | Dept. of Automobile Engineering Bannari Amman Institute of Technology |

| Dr. M. Leenus Jesu Martin | Professor & Head | Dept. of Automobile Engineering, SRM University |

| Dr. G. L. Samuel | Professor | Dept. Mechanical Engineering, IITM, Chennai |

| Mr. A.Sasikumar | Asst. General Manager | Engine & Vehicle Testing, Jeyam Automotive, Coimbatore |

| Mr. S. Karthik | R&D Manager | Ampere Vehicles India Pvt. Ltd, Coimbatore |

| Mr. S. Srihari | Assistant Professor | Dept. Mechanical Engineering, Amrita University, Coimbatore |

| Mr. V. Gowtham | Jr. Engineer | DELPHI-TVS, Kanchipuram |

Department Advisory Board Members

| Mr. K. N. Balaji | Senior Automotive Advisor | – |

| Mr. R. Vasu | Vice President & Corporate Management Representative | Brakes India Pvt ltd |

| Dr. U. Solomon | Scientist G & Additional Director (Special Vehicles) | CVRDE |

| Mr. Ravindra S. Kolhe | R&D Engineer | – |

| Mr. Kasilingam A | Senior Vice President Engineering | Roots Group of Companies Limited |

| Mr. S. Jayabalan | Director, Engineering | Stanadyne India Pvt Ltd |

| Mr. S. Karthik | R&D Manager | – |

| Dr. S. P. Anbuudayasankar | Associate Professor | Department of Mechanical Engineering Amrita School of Engineering |

| Mr. Joseph Chandy | Special Project Manager | JA Motorsports |

Workshop

- WORKSHOP ON GREEN VEHICLE TECHNOLOGY The forenoon session on “The next generation lightweight materials for green vehicles” was conducted by Dr Suresh Nagesh, Chair Professor, PESIT, Bangalore. Dr Arul Mozhi Selvan of NIT, Trichy gave a talk on the the Alternate fuel options for green vehicles. In the afternoon session, Mr. Sudhakar Rao Peram of Dassault Systems Chennai spoke on the real time CAE simulations for automotive industry for optimum design. The global automotive industry is moving towards a green future. The auto world has taken three different paths towards the green route in the form of Electric, Hybrid and Fuel Cell vehicles. With the growing environmental consciousness and the adverse effects of climate change, the Government of India and the governments of various Indian states are supporting many initiatives for the development of ecofriendly technologies, which can reduce the carbon footprint emanating from India. The Indian government, in an effort to move towards non-polluting modes of transport, rolled out the National Electric Mobility Mission Plan (NEMMP) 2020 in January this year with the aim to get 6-7 million Electric and Hybrid vehicles on the roads of India by the year 2020.

- GREEN VEHICLE TECHNOLOGY The session on “The next generation lightweight materials for green vehicles” was conducted by Dr Suresh Nagesh, Chair Professor, PESIT, Bangalore. Dr Arul Mozhi Selvan of NIT, Trichy gave a talk on the the Alternate fuel options for green vehicles. In the afternoon session, Mr. Sudhakar Rao Peram of Dassault Systems Chennai spoke on the real time CAE simulations for automotive industry for optimum design. The global automotive industry is moving towards a green future. The auto world has taken three different paths towards the green route in the form of Electric, Hybrid and Fuel Cell vehicles. With the growing environmental consciousness and the adverse effects of climate change, the Government of India and the governments of various Indian states are supporting many initiatives for the development of eco friendly technologies, which can reduce the carbon footprint emanating from India. The Indian government, in an effort to move towards non-polluting modes of transport, rolled out the National Electric Mobility Mission Plan (NEMMP) 2020 in January this year with the aim to get 6-7 million Electric and Hybrid vehicles on the roads of India by the year 2020.

- DIGITAL PROTOTYPING The Department of Automobile Engineering conducted a workshop on Digital Prototyping on 31st August 2013 for all the Core branches of KCT and which was presented by Mr.S.Rajesh Srinivasan, Autodesk Professional, KKM Soft, Chennai. 75 students of Automobile and other Engineering departments participated in the workshop. The workshop dealt with the role of Autodesk in Automobile Engineering and the discussed about Digital Prototyping using Autodesk. A product demo was also given to the students on Autodesk Inventor software and Autodesk simulation CFD.

- AUTODESK INVENTOR-SHORT TERM TRAINING COURSE In tandem with the MOU signed between Department of Automobile Engineering and Autodesk, a Six week short term value added training was conducted by the Department of Automobile Engineering in Association with Autodesk from the 25th of September to the 7th of November at CEAD (Centre of Excellence in Advanced Design) and about 66 students attended the training and received certificates after the successful completion of training which ended with an examination. All the 66 students expressed that they had benefitted by this training which enhanced their understanding about design. This training is another milestone in the road of the achievements of the department. Similar training will be organized in the future which will strengthen the faculty and students as there are lots of opportunities in the near future for Automotive designs in India.

- AUTOMOTIVE SKETCHING Automotive Sketching is primarily concerned with developing the visual appearance or aesthetics of the vehicle, though it is also involved in the creation of the product concept. The workshop started with a session on ‘Styling of commercial vehicles for 2030’ which was handled by Mr. G Sathiyaseelan, General Manager & Head Styling, Ashok Leyland and followed by ‘Automotive Sketching competition’ for all the participants During the Technical Session on engineering behind Automotive Styling by Mr. M. Vimalathithan, Manager, Trim Engineering COE, Mahindra & Mahindra, Chennai highlighted about the importance of product planning for vehicle development jointly by Engineering and Styling teams. The day ended up with a guest lecture session by Mr. M. Manivannan, General Manager Product Development from Pricol Limited, Coimbatore gave a lecture on Automotive Styling of Passenger Vehicles.

- INTERNATIONAL WORKSHOP ON MOTORSPORTS ENGINEERING

Department of Automobile Engineering conducted INTERNATIONAL WORKSHOP ON “MOTORSPORTS ENGINEERING” on Tuesday, 19th July 2016 in association with ARA Institute of Canterbury, Christchurch, New Zealand. More than 200 engineering students from various colleges across Tamil Nadu were benefited and we had motorsport veterans Mr. Greame Harris, Lecturer Mechanical Engineering from ARA Institute of Canterbury, Mr. N. Leelakrishnan, Chief Technical Director – Red Rooster Performance, Dr. M. Leenus Jesu Martin, Head of Department of Automobile Engineering and Team Principal of various off road, formula and electric vehicle development teams in SRM University and Mr. T. S. Diljith, Founder and Chairman, DTS Racing for the workshop sessions.

Department of Automobile Engineering conducted INTERNATIONAL WORKSHOP ON “MOTORSPORTS ENGINEERING” on Tuesday, 19th July 2016 in association with ARA Institute of Canterbury, Christchurch, New Zealand. More than 200 engineering students from various colleges across Tamil Nadu were benefited and we had motorsport veterans Mr. Greame Harris, Lecturer Mechanical Engineering from ARA Institute of Canterbury, Mr. N. Leelakrishnan, Chief Technical Director – Red Rooster Performance, Dr. M. Leenus Jesu Martin, Head of Department of Automobile Engineering and Team Principal of various off road, formula and electric vehicle development teams in SRM University and Mr. T. S. Diljith, Founder and Chairman, DTS Racing for the workshop sessions. - CRASH COURSE ON MOTORSPORTS ENGINEERING The workshop was conducted on 10.10.2018 with the objective of providing an exposure to the students, young faculty, research scholars and engineers from Aeronautical, Automobile and Mechanical background on advanced engineering concepts related to Motorsport Engineering and Fluid Dynamics. Around 25 participants consisting of students and faculty members from various engineering colleges across Tamil Nadu and Kerala got benefited out of this course.

- TWO DAYS MOTORBIKE OVERHAULING WORKSHOP Two days workshop on motorbike overhauling was conducted on the 16th and 17th of September 2016. The workshop was conducted by Prigma Edutech services Pune. Two professionals from the company Mr.Arpit Goyal and Mr.Manav Garg conducted the workshop. Both of them are graduates from NIT. This workshop was conducted to raised funds for Team Blitzkrieg.

- PRADHAN MANTRI KAUSHAL VIKAS YOJANA Department of Automobile engineering has organized PMKVY- Automobile Service Technician Level 4 for the academic year 2017-2018. The Course has been approved and funded by AICTE through PMKVY – TI. Total of 15 students were registered for the course and 430 Hours of practical and theoretical training were conducted for the students. Mr. K. Damodaran from CAI Industries Coimbatore has conducted practical session during Sundays. Mr. S. Sivakumar and Mr. G. Rajkumar conducted theoretical sessions for the students.

Seminars

- PRODUCT LIFE CYCLE MANAGEMENT SAEINDIA in association with Dept. of Automobile Engineering, KCT conducted the Professional Development Programs on “Product Lifecycle Management” on 13th October 2018 at Kumaraguru College of Technology, Coimbatore.

- ADVANCED VEHICLE DYNAMICS The Department of Automobile Engineering hosted Optimum G – Applied Vehicle Dynamics Seminar for SAE International – Formula Student Participants in India from 29th Jan to 01st Feb 2018 at KCT. The seminar sessions were handled by a Motorsport expert Mr. Claude Rouelle, President – Optimum G, Centennial, CO 80111, USA. We had around 75 participants from IIT – Bombay, Madras & Ropar, VIT, MIT, Manipal University, K.J.S C E, Vishvakarma Institute of Technology and few other engineers from Dubai, Mumbai and Hyderabad.

Competitions

- QUAD BIKE DESIGN CHALLENGE Kumaraguru College of Technology hosted “QUAD BIKE DESIGN CHALLENGE – QBDC 2016” from 22nd to 24th October 2016 at KCT Dirt Track organized by Fraternity of Mechanical and Automotive Engineers (FMAE), Hyderabad.

- KCT MINI DIRT BIKE KCT MINI DIRT BIKE is a National Level Mini-Bike Design and Fabrication contest conducted by Department of Automobile Engineering in association with SAEINDIA KCT Collegiate Club and KCT Automotive Association every year since 2014 in our own Dirt Track which is about 1.6 km length with multiple bends and obstacles testing the student developed mini dirt bike’s performance. Recently on 17th feb 2018, department of automobile engineering organized MINI DIRT BIKE design and manufacturing competition for 60cc and 80cc motorcycles.

- Conversion of IC Engine Passenger Car into Electric Vehicle

- Development of a Flow Bench

- Development of Metal Matrix Aluminium Alloy Composites for Automotive and aerospace applications

- Performance Tuning of V8 engine in collaboration with ARA Institute of Canterbury, New Zealand, using Vannik Developments Engine Simulation software suites.

- Performance Assessment of Carburetor in a 100cc Motorcycle in collaboration with ARA Institute of Canterbury, New Zealand

- Development of Car Seat for Physically Challenged People

- Prevention of Car Window Jamming

- G Thenmozhi (2017) MODELING AND SIMULATION OF POWER CONVERTERS FOR POLYMER ELECTROLYTE MEMBRANE FUEL CELL, Journal of Advanced Research in Dynamical and Control Systems Vol. 9. 14-Special Issue pp (1239-1244) http://www.jardcs.org/abstract.php?archiveid=1844

- Satish S (2016) FATIGUE BASED DESIGN AND ANALYSIS OF WHEEL HUB FOR STUDENT FORMULA CAR BY SIMULATION APPROACH, IOP Conf. Series: Materials Science and Engineering 149 012128 doi:10.1088/1757-899X/149/1/012128

- J D Andrew Pon Abraham (2017) DESIGN AND ANALYSIS OF LCV CHASSIS (TATA 407), Journal of Advanced Research in Dynamical and Control Systems Vol. 9. (1245-1256). http://www.jardcs.org/abstract.php?archiveid=1845

- S Sivakumar (2017) DEVELOPMENT OF ECO-FRIENDLY EMISSION CONTROL UNIT USING TIO2 COATED CATALYTIC CONVERTER, Journal of Advanced Research in Dynamical and Control Systems Vol. 9. (1222-1229). http://www.jardcs.org/abstract.php?archiveid=1842&action=fulltext&uri=/archives-special.php?year=2017&issue=14-Special%20Issue&page=10

- S Satish (2017). DESIGN AND ANALYSIS OF SUSPENSION SYSTEM FOR A THREE WHEELER ELECTRIC VEHICLE, Journal of Advanced Research in Dynamical and Control Systems Vol. 9. 14-Special Issue pp (1230-1238) http://www.jardcs.org/abstract.php?archiveid=1843

- Prabhakaran A (2017) LOW POWER REAL TIME SURVEILLANCE CCTV RECORDING USING MSP430, Research Journal of Engineering and Technology, 8(4), 365-368. http://ijersonline.org/AbstractView.aspx?PID=2017-8-4-14

- Kishore R (2018) PERFORMANCE IMPROVEMENT OF RACING ENGINE USING SIMULATION STUDY AND EXPERIMENTAL VALIDATION, Journal of International Journal of Pure and Applied Mathematics Vol.118 (19-25). http://www.ijpam.eu

- J D Andrew Pon Abraham, M Mohanraj (2018) THERMODYNAMIC PERFORMANCE OF AUTOMOBILE AIR CONDITIONERS WORKING WITH R430A AS A DROP-IN SUBSTITUTE TO R134A, Journal of Thermal Analysis and Calorimetry, 1-16.

- S John Alexis, P S Samuel Ratna Kumar, K R Vinoth, V Vijay Ragul and N Saran Kumar (2018) IMPROVED MECHANICAL PROPERTIES OF AA5083 REINFORCED WITH MULTIWALL CARBON NANOTUBES FOR AUTOMOBILE APPLICATIONS, Int. J. Vehicle Structures & Systems, 10(4), 278-281. doi: 10.4273/ijvss.10.4.10

- Thenmozhi G & Kumaresan M, ELECTRONIC DIFFERENTIAL CONTROLLER FOR ELECTRIC VEHICLE, International Journal of Mechanical and Production Engineering Research and Development (IJMPERD) Vol. 8, Special Issue 7, Oct 2018, 473-482

- Rajkumar G, Naveen Kumar C, Arul Pandiyan S & Jayasurya S (2018) DEVELOPMENT OF IMAGE ACQUISITION SYSTEM TO ELIMINATE BLIND SPOT OF A-PILLAR, International Journal of Mechanical and Production Engineering Research and Development (IJMPERD).Vol. 8, Special Issue 7, Oct 2018, 145-151

- C Naveen Kumar, G Rajkumar, B Sethubalan, V Sarath Kumar & V. Dineshkumar (2018) MEASUREMENT OF VIBRATION IN DIFFERENT PARTS OF THE TWO WHEELER AND ITS HARMFULNESS TO HUMAN BODY, International Journal of Mechanical and Production Engineering Research and Development (IJMPERD), Vol. 8, Special Issue 7, Oct 2018, 493-501

- T Karthik, G Thenmozhi & G Hariharan (2018) SIMULATION OF CRUISE CONTROL SYSTEM USING DSPACE WITH DIFFERENT CONTROLLERS, International Journal of Mechanical and Production Engineering Research and Development (IJMPERD).Vol 8, Special Issue 7, Oct 2018, 461-472

- R Kishore, B Arun, S John Alexis, T Hari Prasath, P Monish Arya (2018) SINGLE PEDAL MECHANISM FOR LEG AMPUTATED PERSON AND FOR THE REDUCTION OF REACTION TIME, FISITA World Automotive Congress, F2018/F2018-VCP-053, Oct 2018. https://www.fisita.com/resources/papers/F2018/F2018-VCP-053

- G Hari Vignesh and A Prabhakaran 2018 AUTOMATIC CAR WINDOW OPENING SYSTEM DURING ACCIDENTS FISITA World Automotive Congress, F2018S-APS-085, Oct 2018.

| Name of the faculty | Year of publication | Title of paper | Name of Journal |

|---|---|---|---|

| Prabhakaran, A., Annamalai, V., Dineshvikram, B., & Julash,T | 2021 | Design of ECU for Automatic Headlight Beam Control during City Driving | Int. J. Vehicle Structures & Systems |

| Baskar, S., Kumar, D. S., Dhinakaran, R., Prabhakaran, A., Arun, B., & Shanmugam, M. | 2021 | Experimental studies on mechanical and morphological property of the natural and SBR/BR hybrid rubber | Materials Today: Proceedings |

| Prabhakaran, A., Krishnan, K. S., Dhinakaran, R., Baskar, S., & Shaisundaram, V. S, | 2021 | Analysis of the efficiency of an automotive alternator by replacing mild steel into aluminum as a material for rotor | Materials Today: Proceedings |

| Saravanakumar, S., Chandramohan, N. K., Prabakaran, S. T., Muniyappan, M., Shanmugam, M., & Shaisundaram, V. S.. | 2021 | The static structural analysis of torque converter material for better performance by changing the stator angle | Materials Today: Proceedings |

| Chandramohan, N. K., Shanmugam, M., Sathiyamurthy, S., Prabakaran, S. T., Saravanakumar, S., & Shaisundaram, V. S | 2021 | Comparison of chassis frame design of Go-Kart vehicle powered by internal combustion engine and electric motor | Materials Today: Proceedings |

| Chandramohan, N. K., Rajkumar, G., Bhuvendran, A., & Alexis, S. J | 2020 | Fabrication and testing of short fiber composites made of used brush bristles as reinforcement combined with epoxy matrix | Materials Today: Proceedings |

| Thenmozhi G | 2020 | PAPR reduction of MIMI-OFDM with reduced computational complexity SLM Scheme, https://doi.org/10.1016/j.matpr.2020.08.498 | Elsevier Materials Today: Proceedings |

| Thenmozhi, G., Cherian, M., & Nirmala, M | 2020 | Impact analysis on change in climatic conditions due to the development of highway roads and other infrastructures at Coimbatore-an evidence | IOP Conference Series: Earth and Environmental Science |

| Radhika, A., Thenmozhi, G., Balakarthikeyan, M., & Stalin B | 2020 | Enhancement of welding strength through electric current and resistance on ERSW process using chromium steel | Materials Today: Proceedings |

| Thenmozhi, G., Cherian, M., Nirmala, M., & Lalitha, R | 2021 | An intensive online survey of climate change due to development of roads and bridges on the highway road at Coimbatore–an evidence | IOP Conference Series: Materials Science and Engineering |

| Thenmozhi, G., Cherian, M., Nirmala, M., & Lalitha, R | 2021 | Effect of destruction of trees on highway roads and its impact on climate change at Coimbatore–a case study | IOP Conference Series: Materials Science and Engineering |

| Subramaniam, M., Muthiya, S. J., Satish, S., Joshuva, A., & Alexis, J. (No. 2020-28-0499). | 2020 | Numerical Investigation on Various Layouts of Phase Change Materials Based Battery Module Used in Electric Vehicles | SAE Technical Paper. |

| Joshuva, A., Anaimuthu, S., Selvaraju, N., Muthiya, S. J., & Subramaniam, M. (No. 2020-28-0496) | 2020 | A Machine Learning Approach for Vibration Signal Based Fault Classification on Hydraulic Braking System through C4. 5 Decision Tree Classifier and Logistic Model Tree Classifier | SAE Technical Paper. |

| Thenmozhi. G, Nithya Priya | 2020 | Studies on the medicinal herbs to cure Polycystic Ovarian Syndrome (PCOS) – A review | Recent trends in food process engineering sector -Nutraceuticals and Functional Foods |

| Thenmozhi. G, Nithya Priya, Suguna | 2020 | Agri Image Processing using Uml Model | Bioscience Biotechnology Research Communications |

| B Kalidasan,Divyabharathi ,AK Pandey, Subramaniyan ,Mohankumar | 2020 | Technological Advancement of Solar Thermal System Desalination Process – A Review | IOP Conference Series: Materials Science and Engineering |

| S.Satish, S. John Alexis , Arun Bhuvendran, Mohanraj Shanmugam, S. Baskar, V.S. Shaisundaram | 2021 | Design and analysis of mild steel mini truck body for increasing the payload capacity | Materials Today Proceedings |

| S. Tamil Prabakaran, P. Sakthivel, Mohanraj Shanmugam, S. Satish, M. Muniyappan, V.S. Shaisundaram | 2021 | Modelling and experimental validation of TIG welding of INCONEL 718 | Materials Today Proceedings |

| Mohankumar Subramaniam, S Jenoris Muthiya, Satish S, Joshuva A, John Alexis | 2020 | Numerical Investigation on Various Layouts of Phase Change Materials Based Battery Module Used in Electric Vehicles | SAE Technical Paper |

| R. Dhinakaran, R. Muraliraja, R. Elansezhian, S. Baskar, S. Satish, V.S. Shaisundaram | 2021 | Utilization of solar resource using phase change material assisted solar water heater and the influence of nano filler | Materials Today Proceedings |

| Mr. G. Rajkumar, & Dr. K. Rathanakumar | 2021 | Grid Based Blind Spot Analysis for Indian Driver Anthropometry | |

| Abraham, J. A. P., Mohanraj, M., Selvakumar, M., & Raj, A. K, 43(3) | 2021 | Experimental assessments on R430A as an environment-friendly replacement to R134a in vehicle air conditioners | Journal of the Brazilian Society of Mechanical Sciences and Engineering |

| Dr.G.Thenmozhi | 2020 | Analysis of double chambered single and cascaded microbial fuel cells: characterisation study based on the enrichment of fuel. | International Journal of Intelligent Enterprise |

| Bhuvendran, A., & Prabhakaran, A | 2020 | Performance evaluation of air cushioned seat in a motorcycle | Materials Today: Proceedings |

| Mohankumar Subramanian, S Satish, Jenoris Muthiya Solomon, Ravishankar Sathyamurthy | 2020 | Numerical and experimental investigation on capture of CO2 and other pollutants from an SI engine using the physical adsorption technique | Heat Transfer |

| Mohankumar Subramaniam a , Jenoris Muthiya Solomon b,∗ , V. Nadanakumar b , Shridhar Anaimuthu b , Ravishankar Sathyamurthy | 2020 | Experimental investigation on performance, combustion and emission characteristics of DI diesel engine using algae as a biodiesel | Energy Reports |

| Chandramohan, N. K | 2020 | Variation in compressive and flexural strength of the carbon epoxy composites with the addition of various fillers to the epoxy resin | Materials Today: Proceedings |

| Mohanraj, M., & Abraham, J. A. P | 2020 | Environment friendly refrigerant options for automobile air conditioners: a review., | Journal of Thermal Analysis and Calorimetry |

| Dr. John Alexis. S | 2017 | Modal analysis of MWCNT reinforced AA5083 composite material | International Journal of Civil Engineering and Technology |

| Optimization of high speed CNC end milling process of BSL168 aluminium composite for aeronautical applications | Transactions of the Canadian society for mechanical engineering | ||

| Prof., Sivakumar S, Mr. S.Satish | 2018 | Development of eco-friendly emission control unit using TIO2 coated catalytic converter | Journal of advanced research in dynamical and control systems |

| Dr.Thenmozhi G, Dr. John Alexis. S | 2017 | Modelling and simulation of power converters for polymer electrolyte membrane fuel cell | Journal of advanced research in dynamical and control systems |

| Mr.AndrewPon Abraham J D,Dr. John Alexis. S,Mr. Naveen Kumar C,Mr.Rajkumar G,Mr.Kishore R | 2017 | Design and analysis of LCV chassis (tata 407) | Journal of advanced research in dynamical and control systems |

| Mr.Satish S | 2017 | Fatigue based design and analysis of wheel hub for Student formula car by Simulation Approach. | Materials Science and Engineering |

| Mr.Satish S, Mr. Saiganesh J, Mr.Karthik T | 2017 | Design and analysis of suspension system for a three wheeler electric vehicle. | Journal of advanced research in dynamical and control systems |

| Mr.Rajkumar G | 2018 | Review on non-traditional machining of metal matrix composites | International journal for research in applied science and engineering technology |

| Mr.Prabhakaran A | 2017 | Low Power Real Time Surveillance CCTV Recording using Msp430 | Research Journal of Engineering and Technology |

2018-19

| Project Title | Funding Agency | Amount (Rupees) |

|---|---|---|

| Shaft and bearing analysis of micro tunnel boring machine (MTBM) | Raj Conbuild Limited -Delhi | 454000.00 |

| Two Wheeler Performance Testing – Chain Slag Measurement (Honda Activa) | LG Balakrishnan & Bros. Ltd | 1000.00 |

| Two Wheeler Performance Testing (Honda Activa) | LG Balakrishnan & Bros. Ltd | 2000.00 |

| Two Wheeler Performance Testing | LG Balakrishnan & Bros. Ltd | 8000.00 |

| Skill development training project | ALTRAN | 480000.00 |

| Program for Graduate Engineering Trainee | ALTRAN | 400000.00 |

2017-18

| Project Title | Funding Agency | Amount (Rupees) |

|---|---|---|

| Calorific value of coal | Cheran Steels Private LTD | 2000.00 |

| Calorific value of coal | Cheran Steels Private LTD | 1000.00 |

| Calorific value of coal | Cheran Steels Private LTD | 2000.00 |

2019-20

| Project Title | Funding Agency | Amount (Rupees) |

|---|---|---|

| Study of Manufacturing process to Develop Canister Dome Shround | Defence Research and Development Laboratory | 998000.00 |

| Design and development of data acquisition system and power controller for solar installations | Ezone Energy solutions Pvt Ltd. | 800000.00 |

| Prototype of solar tracker controller | Ezone Energy solutions Pvt Ltd. | 1200000.00 |

| Entrepreneurship Awareness Programme | Department of Science and Technology-NIMAT Project | 20000.00 |

| Impact Analysis on Climatic conditions due to the development of Highway Roads and other Infrastructures | Indian Council of Social Science Research – Minor project | 300000.00 |

2018-19

| Project Title | Funding Agency | Amount (in Rupees) |

|---|---|---|

| Mechanical Modification and Integration of Electric Powertrain components for Tractor electrification | Robert BOSCH, Coimbatore | 1300000.00 |

| Development of driver safety system to avoid accidents | Tamilnadu State Council for Science and Technology | 7500.00 |

2017-18

| Project Title | Funding Agency | Amount (in Rupees) |

|---|---|---|

| Development of special car seat for physically challenged people | Tamilnadu State Council for Science and Technology | 8000.00 |

| Development study of copper tulip liner for choosing appropriate manufacturing process based on FE simulation | Defence Research and Development Laboratory – Hyderabad | 920000.00 |

| Automotive Service Technician Level – 4 | Pradhan Mantri Kaushal Vikas Yojana – TI scheme | 274000.00 |

| Prevention of car window jamming (Sponsored Electronic components) | Texas Instrument | 13000.00 |

| Year | Name of Inventor/Applicant | Title of Invention | Application No and date of filing | Status |

|---|---|---|---|---|

| 2020 – 2021 | Dr.G.Thenmozhi | Portable Millet Popping Machine and method thereof | 202041056868, Date: 29.12.2020 | Filed |

| 2020 – 2021 | Mr.A.Prabhakaran | Faya SHEBEI | 202141005618 Date: 19.02.2021 | Filed |

| 2017 – 2018 | Mr.S.Sivakumar, | Internal combustion Engine with circulating Pistons | TEMP/E1/14473/2018- CHE & 11.04.2018 | Filed |

| Dr.JohnAlexis.S, | Adaptive Rollover Repositioning System for 4 Wheeled Motor Vehicle | 201841011688 & 28/03/2018 | Filed | |

| Mr.R.Kishore, | ||||

| 2016 – 2017 | Dr. John Alexis.S, | Method and System for Remotely adjusting Height and Angle of a Wall Mounted Television Fixer | 201741012456 and 06.04.2017 | Granted |

SAEINDIA KCT Collegiate Club

SAEINDIA Collegiate clubs provide many benefits to SAE members like tangible contact with their future profession & various objectives on engineering education. The purpose of this Collegiate Club is to increase the benefits of SAEINDIA student membership through special activities. SAEINDIA KCT Collegiate Club is a Chapter of Society of Automotive Engineers (SAE-INDIA), Southern Section established in 2014. Currently this collegiate club has more than 300 students from Mechanical, Mechatronics, Automobile and Aeronautical Engineering Department.

The following activities have been organized by SAEINDIA KCT Collegiate Club:

- SAEINDIA Student Convention

- Guest Lectures, Seminars and Workshops

Our members have been taking part in the following SAE India Programs every year

- BAJA

- SUPRA

Facebook Page : https://www.facebook.com/saekctcc/

Email : [email protected]

Department Association

Automobile Engineering Association (AEA) was formed and inaugurated by Mr. J Balamurugan and Mr. Sajeev Mathew Rajan, Directors of Spitfire Performance Automotive Pvt Ltd on 12th March 2013 and the Faculty Advisor Mr. L Shanmugaraj introduced the Office Bearers. The Automobile Engineering Association transformed as KCT Automotive Association with more responsibilities focusing on student self learning, self organising, exposure to external world for technical and entrepreneurial skills, leadership, campus quality improvement & awareness about the environment. The new executive members for the year 2016-17 introduced by Mr. R Kishore, Faculty Advisor and our association was inaugurated by Mr. V L Samy, General Manager – Engineering Services, Jayem Automotives Pvt Ltd on 19th September 2016. Along with the technical activities the KCT AA will contribute for

- Employability skill development training programs with national or international professional bodies

- Holistic Development – Corporate Immersion, Alumni Interaction, Student Profiling.

- Department Infrastructure development – Building maintenance, setup of new labs, updating the labs.

- Curriculum and Syllabi Framing

- Academic Grievances

- Department Newsletter and Magazine

- Student Welfare Activities

This year KCT Automotive Association is lead by our student president Mr G R Mothilal Design. In the inauguration ceremony Dr. S. John Alexis, HoD, Department of Automobile Engineering welcomed the gathering and listed out the annual report of the AEA 2017-2018. Following this Principal Dr. Senthil J, gave his speech to enlighten the young minds . The chief guest for the event was Mr. Karthik S, who is the R&D manager in Ampere Vehicles India Private Limited. Facebook Page : https://www.facebook.com/automobileengineering.kct

KCT Automotive Association was inaugurated by Mr. Krishna Kumar, General Manager – Artemis Volvo Auto India Pvt. Ltd for the year 2017-18 led by our student president Arul Pandiyan S.

Formula Student Team

Sakthi Racing is a student organization at Kumaraguru College of Technology composed of Undergraduate students from diverse disciplines. The team designs, fabricates an open-wheel race car against other universities nationally in formula student competitions which includes dynamic and static events to test the team’s knowledge of design, manufacturing and marketing of the formula one car. Over the years, the team has attended competitions namely SAE Supra in The Buddh International Circuit, Greater Noida, and Formula Bharat in Kari Motor Speedway, Chettipalayam, Coimbatore. Sakthi Racing provides students with a great opportunity to learn about engineering design, and manufacturing for engineering majors. Each component of the car is designed by students and manufactured in our Garage at KCT. Along with the engineering majors, Sakthi Racing also has a business side which includes accounting, web development, marketing, and media. There are many different roles within the team and always encourages students to join.

- Business Team

- Engineering Team

- Powertrain

- Chassis

- Marketing

- Engine Calibration

- Frame – Roll Cage

- Finance

- Cooling

- Brakes

- Social Media

- Intake & Exhaust

- Suspension

- Drivetrain

- Electrical

Facebook Page : https://www.facebook.com/sakthiracing/

Email : [email protected]

All Terrain Vehicle Team

Blitzkrieg represents KCT in SAE BAJA event conducted annually in NATRIP facility, Pithampur, Madhya Pradesh. Innovation and perseverance of our team enriched with practical skills, have always paved our way in the quest to perfect our ATV design.

Facebook Page : https://www.facebook.com/teamblitzkriegracing/

Automotive Systems Design Manufacturing and Integration

Department of Automobile Engineering had organized One Day National Conference on “Automotive Systems Design Manufacturing and Integration” at KCT on 28th April 2018. We have received total of 73 papers out of which 19 papers have been accepted for publication. In these 6 papers are form KCT faculty and 13 Papers form external participants. The selected papers are to be published in Scopus Indexed and UGC approved journal “International Journal of Vehicle Structures and Systems (IJVSS)”.

National Conference on recent Advancements in Automotive Systems Design, Manufacturing and Integration

Department of Automobile Engineering conducted a National Conference on Recent advancements in Automotive system design, Manufacturing and Integration on 28th Mar 2015, bringing together academia, scientists, researchers, e engineers, r research scholars and s students (both UG & PG) from different universities, colleges and laboratories to exchange and share their knowledge, experiences and research results about all aspects of Design including Engine Design, Transmission system design, steering system design, Braking system design, Fuel Injection & Ignition system design, Optimization in design. Manufacturing including Materials for Manufacturing, Advanced manufacturing and integration of all the systems like Infotronics, Safety systems and Control systems in order to discuss the challenges encountered and the solutions adopted and hence to enhance their development and facilitate the emergence of new technologies in Automobile industry in our country. This Conference was conducted with industry focused sessions where the leading experts in the field presented their views on the Automotive systems design, Manufacturing and Integration. Novel designs of automotives, components, sub assemblies, assemblies and systems was discussed at the end of each session. Newer safety devices, information gadgets and the interfacing hardwares were addressed in the System integration session.

AUTODESK KCT has signed a Memorandum of understanding (MOU) with KKM Soft. Pvt. Ltd, Chennai for conducting short term courses on Autodesk Inventor for training students from II and III year Automobile Engineering. The first course was conducted for a batch of 66 students ting from 25th September to 7th November 2013 after regular working hours of the college.

ARA INSTITUTE OF CANTERBURY KCT has signed a MOU with Ara Institute of Canterbury, New Zealand for Faculty Exchange and International certification program on Motorsports Engineering. 6 Students and a Faculty visited ARA during Feb 2017 and completed a certification course.The highlights of the course contents are mentioned below, KCT has signed a MOU with Ara Institute of Canterbury, New Zealand for Faculty Exchange and International certification program on Motorsports Engineering.

- Wind Tunnel testing

- Dyno Testing with Link ECU

- Formula Race Karting – Driver & Race engineer experience

- Vehicle Data-logging

- CAD – Formula Car Frame Design

- Engine simulation

- Industrial visits – Martin JetPack, Sprintec, Aeromotors and others

- Hands on training of performance tuning in race cars, karts, race motorcycles

SUMMER SCHOOL RESEARCH PROGRAMS KCT has signed MoU’s for International Summer School & Research Programs with

- Loughborough University, UK.

- University of Southampton, UK.

- The University of Leeds, UK.

- Tel Aviv University, Isrel.

- RWTH Aachen University, Germany.

- The Ara Institute of Canterbury, New Zealand

REPUBLIC MOTORS MOU was signed with Republic Motors, Dausa, Rajasthan on 7th Dec 2015 for the conduction of Skill Development Program for International Go-Kart Championship 2015-16 and KCT was named as the location partner for the 3 day skill development program on vehicle dynamics from 28th Jan 2016 to 30th Jan 2016.

FMAE Memorandum of Understanding was made on 9th July 2016 between Fraternity of Mechanical and Automotive Engineers (FMAE) and Kumaraguru College of Technology for conducting FMAE – Quad Bike Design Challenge.